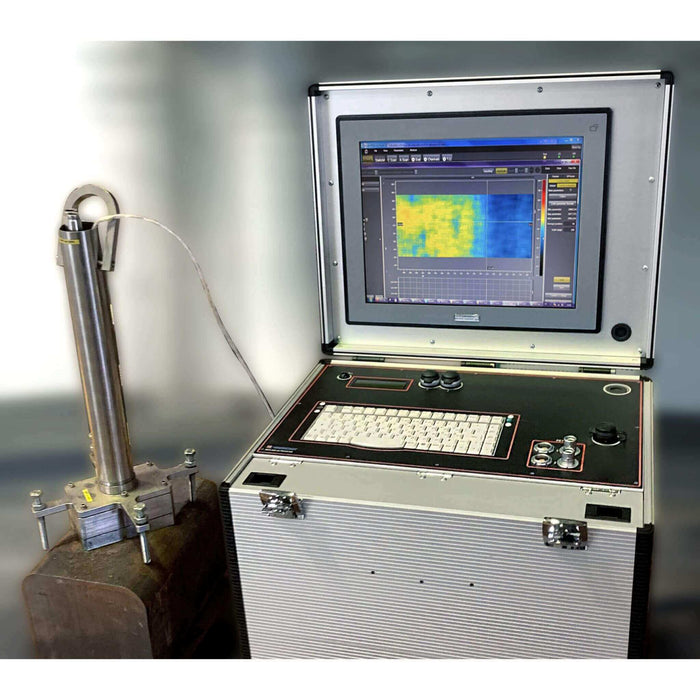

Sonaflex (Liquid Core)

The Sonaflex (Liquid Core) highlights one of the main advantages of EMAT technology: the absence of water coupling. This makes high-temperature material testing possible. This system allows material temperatures up to 1200°C, which is necessary as the system is intended for the examination of blooms coming directly off the continuous casting line.

The main task of the system is determining the location along the length where the presence of a liquid core is in the cast bloom. Knowing the exact position of the liquid core is extremely important for choosing the correct position for cutting the bloom to avoid liquid metal losses, which lead to equipment damage, material scrap rates, and a reduced lifespan of production lines. The system continuously monitors the supplied blooms for the presence of the liquid core and continuously updates the operator or mill control system where solidification has occurred along the length, thus preventing any risk for personnel or equipment.