Resonance Testing can be used for the detection of any internal or external flaws in a material and or component by sending signals throughout the whole part. Imperfections, such as variances in overall shape, weight and density of parts can be detected as well. This method can even detect defects in the Heat Treating and Machining processes.

In Resonance Testing, every part has it's own unique frequency when hit with the testing hammer, but all of the good parts display a similar frequency signaling that it's a good part and passes the test. However, a bad part would show a different frequency range, signaling that it didn't pass the test and has some sort of internal and or external defect. It's similar to a bell in perfect condition versus a bell with a crack. One bell would send back a normal frequency bell, while the cracked one, would have a different frequency indicating that it has some sort of defect.

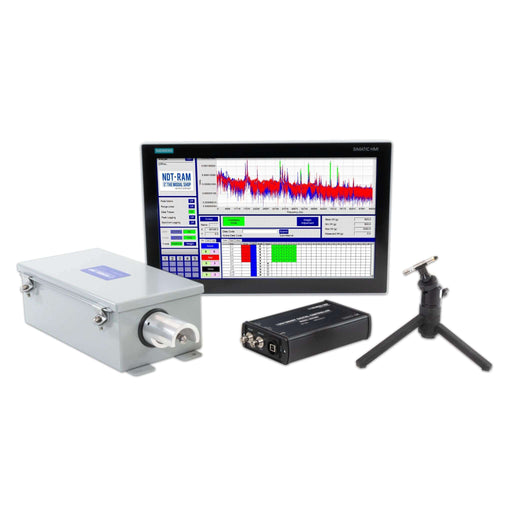

Getting started with Resonance Testing is a simple process as well, we get a sample size of good parts that we test with the system and then proceed to use that data for the pass/fail criteria in the future.

To learn more about our partner, The Modal Shop Inc., specialists in Resonance Inspection Systems, click here.