The Primary Metals Industry includes iron, steel, aluminum, copper, nickel, titanium, and their alloys. These metals are most commonly used in a wide range of industrial applications, including manufacturing, construction, transportation, and energy production.

Iron is a metallic element that is abundant on earth and is used in the manufacturing of products such as steel, cast iron, and wrought iron.

Steel is an alloy of iron and carbon that is widely used in manufacturing due to its strength, durability, and versatility.

Aluminum is a lightweight and corrosion-resistant metal that is commonly used in the manufacturing of products such as aircraft, automobile parts, and household appliances.

Copper is a highly conductive metal that is used in a wide range of applications, including electrical wiring, plumbing, and electronics.

Nickel is a versatile metal that is used in the production of stainless steel, rechargeable batteries, and specialty alloys.

Titanium is a lightweight and strong metal that is highly resistant to corrosion, making it ideal for use in biomedical implants, aerospace applications, and other demanding environments.

Alloys are materials that are composed of two or more metals, or a metal and a nonmetal, that are combined to create a new material with improved or unique properties. The process of creating alloys involves melting and mixing the metals together, which results in a uniform material.

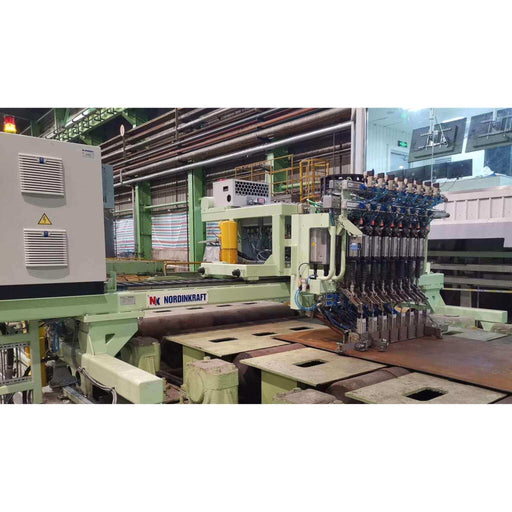

NDT inline, early in the production process, assures that only high-quality material is being manufactured, thus eliminating the production of a high volume of scrap when the process goes off track. NDT on final products ensures high quality as well as conformance to customer requirements and industry codes and standards.