Meet NDT-RAM

Resonance Inspection Delivers 100% Quality Inspected Parts

In the world of manufacturing today, the potential liability of shipping a defective part is catastrophic to you, your customer and the consumer. Resonant Inspection via Non-Destructive Test Resonant Acoustic Method (NDT-RAM™) is designed to help you deliver fully inspected parts, economically and on time, giving you confidence in the quality of your parts.

The principle of NDT-RAM is simple. Every part has a unique resonant signature or pattern that reflects its composition. Any deviation from the expected signature or pattern indicates the presence of a structural flaw or variation. A familiar example is a cracked bell that no longer has a clear ring and cannot hold its tone. Learn more about how NDT-RAM compares to other methods of non-destructive testing and non-destructive inspection.

NDT-RAM detects imperfections such as variances in dimension, geometry, weight, density, bonding, voids, cracks and missed manufacturing processes. The entire procedure takes approximately 3 seconds per part, allowing for efficient quality control testing of all the parts in your process line.

Who needs NDT Resonant Inspection?

Manufacturers or users of metal parts that:

-

Have substantial inspection cost

-

Require 100% inspection of their parts

-

Desire to improve quality of their parts

-

Produce and/or use safety-critical parts

-

Have customers demanding higher quality

-

Have substantial scrap costs due to false rejects

What can NDT Resonant Inspection detect?

-

Cracks, chips, and holes

-

Out-of-tolerance dimensions

-

Variations in hardness

-

Residual stress

-

Machining or heat-treating processes

Highlights

-

No "part preparation" required

-

Inspection in one to three seconds per part, typical*

-

Reduction of scrap costs with elimination of false rejects

-

Process compensation for common process variables

-

Easy to learn and use application software

-

Report generation, including statistical analysis

-

Industrial package - NEMA4 enclosure, sealed PC

-

Same system can test many different parts

-

Confidence that all tested parts are defect-free

Resonance Systems

RAM–AUTO Automated Resonance Inspection System

The Modal ShopThe RAM–AUTO is a 100% in–line fully automated turnkey resonant inspection system with an automated conveyor and industrial grade computer that's c...

View full detailsRAM-DROP Automated Resonance Inspection System

The Modal ShopThe RAM-DROP is a 100% automated fast turnkey Resonance NDT inspection system for small parts with automatic sorting of defective parts. The system...

View full detailsRAM-TEST-FIXTURE Resonance Workstation

The Modal ShopThe RAM-TEST-FIXTURE is a resonant inspection workstation with an adjustable platform for easy testing of various part sizes and shapes. This sys...

View full detailsRAM-TEST-MANUAL Portable Resonance System

The Modal ShopThe RAM-TEST-MANUAL is a portable manual system that’s ideal for spot checks and troubleshooting in the field and new part set-up. This system is...

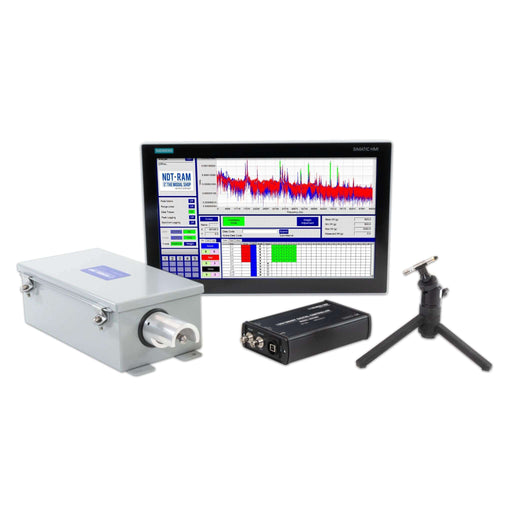

View full detailsRAM-TEST-SEMI Resonance System

The Modal ShopThe RAM-TEST-SEMI is a resonant inspection system that’s ideal for integration into an existing manufacturing process. The system includes all of...

View full details